Custom Sheet Metal Fabrication & Manufacturing

Every product and component at Interhange Electronics is meticulously crafted using advanced CNC shearing, CNC punching, and CNC forming equipment for sheet metal fabrication.

Our Products

Manufactured Metal Products

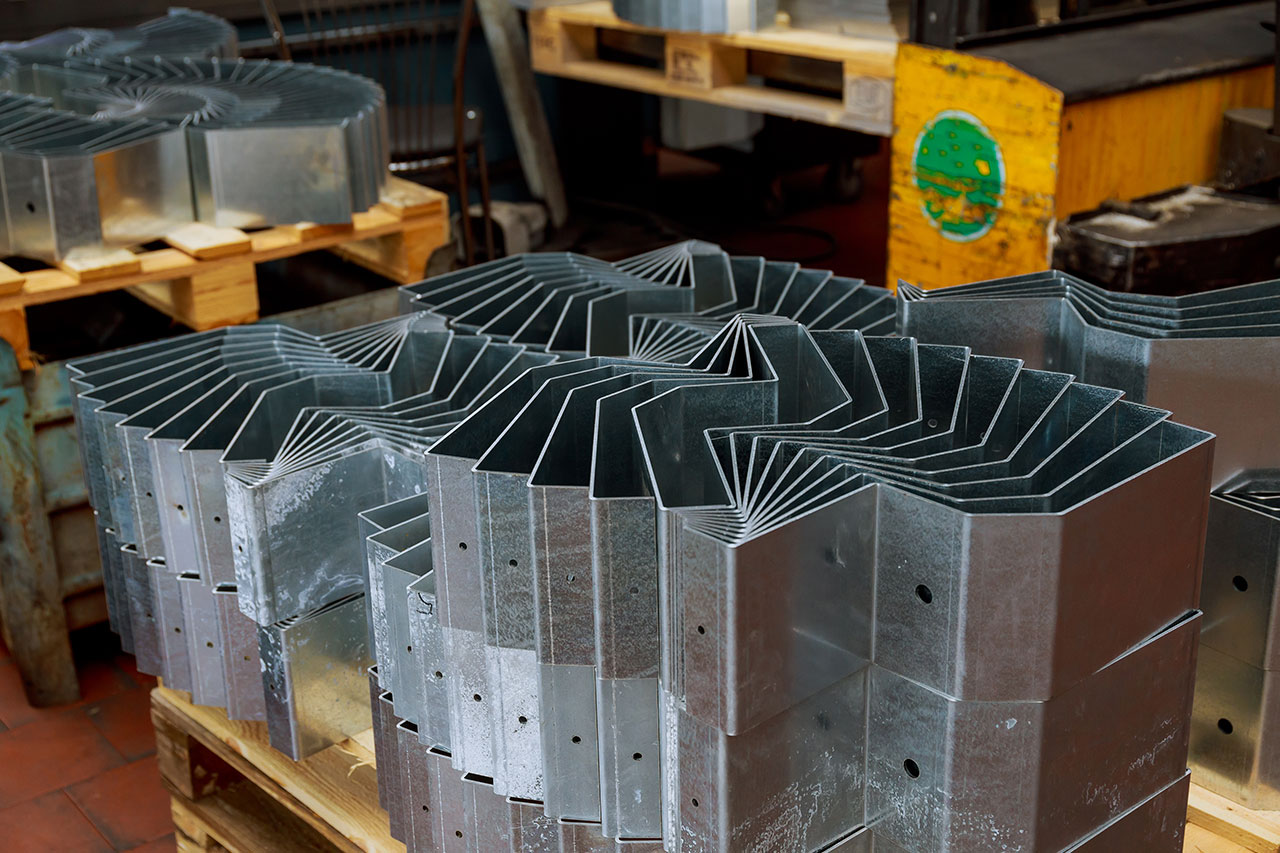

Interhange Electronics is capable of manufacturing virtually any sheet metal part, from simple faceplates to components with complex geometries. Our custom metal parts have ranged from stainless steel UV water treatment enclosures to parts used in space, such as those installed on the Canadarm.

Custom Sheet Metal Fabrication

Precision Sheet Metal Fabrication | Power Supply Enclosures

Interhange Electronics specializes in custom power management enclosures, designed to exact client specifications for optimal performance and longevity. With extensive experience in various enclosure types, we ensure high-quality, problem-free products.

Electronics Chassis

We offer chassis enclosures in various space-saving sizes to meet your specific board and equipment configuration needs. These can include PCB board shrouds, fan brackets, heat sinks, bus bars, mounting plates, card guides, EMI shields, rack mount brackets, and more.

Sheet Metal Fabrication Sub-Assembly

Beyond manufacturing sheet metal parts, we provide complete products from simple sub-assemblies to turnkey production assemblies, including specialized packaging solutions. Our sub-assembly capabilities include:

- Grounding straps

- Lexan doors

- Terminal block installation

- Hinges

- Card guide installation

- Many other possibilities

Custom Sheet Metal Fabrication in Toronto

Utilizing CAD and engineering software, we can accept design files, create our own from 2D drawings, or offer complete design assistance. Our advanced CAM software flattens 3D design files for precision cutting and forming of custom parts. Our advanced nesting algorithm maximizes material usage, while CNC shearing, punching, and forming ensure precise fabrication.

Interhange Electronics Offers Value-Added Capabilities:

- Consultation

- Design

- Assembly

- Quality control

- Just-in-time delivery

- Local delivery

Precision & Accuracy in Custom Sheet Metal Fabrication

Our electro-mechanical assembly services complement our state-of-the-art sheet metal fabrication, ensuring high accuracy and quality. We offer turnkey solutions with finishing options, silk screening, pad printing, kitting, mechanical assembly, and custom packaging to meet specific customer needs. All processes adhere to ISO-9001 certified procedures to ensure dimensional and critical component accuracy.

Ordering custom metal products is simple with Interhange Electronics. Provide us with a hardcopy or electronic drawing, 3D model, 2D drawing, or a physical sample. Meetings with our design staff and design assistance are available if needed.

Interhange Electronics: A Technology-Driven Custom Metal Part Manufacturer

Based in Canada with decades of experience, we understand the unique requirements of various industries and excel in precision sheet metal fabrication. We maintain ISO 9001:2015 certification, utilizing Solidworks CAD and RADAN CAM software for detailed designs and efficient manufacturing.

Expert Mechanical Design Assistance

We have extensive experience with high voltage cabinets, chassis fabrication, rack mount parts, automated kiosks, telecommunication parts, and aerospace sheet metal fabrications. Our quality-certified processes produce sophisticated, custom precision metal fabrications to exacting standards.

Interhange Electronics advises on Design for Manufacturing (DFM), offering insights into design feasibility, cost reduction, quality improvement, and performance enhancements. We are the preferred choice for companies seeking precision sheet steel fabricating.

QUALITY FINISHING

Available Finishing Options

Powder Coating

Electro-Plating

Electro-plating is frequently used for steel parts to provide corrosion resistance, enhance visual appeal, and modify electrical conductivity. Our qualified vendors deliver high-quality, cost-effective plating solutions in zinc, tin, and nickel, as well as stainless steel passivation and copper or brass bright dip. These processes comply with ROHS standards.

Aluminum Finishes

Anodizing creates a durable, corrosion-resistant layer on the surface of aluminum. This process offers a variety of colors for an attractive and protective finish.

Alodine / Chromate Conversion

Compliant with MIL-DTL-5541 standards, alodine or chromate conversion is a cost-effective coating that provides corrosion resistance while maintaining electrical conductivity. This finish is available in clear or yellow/gold and adheres to ROHS requirements.

Silk Screen Printing

Silk screen printing offers a final decorative or schematic finish with a wide selection of colors. This method is ideal for branding products, enhancing brand recognition, and marking parts with symbols, port numbers, caution statements, or any desired graphics or text. Silk screen printing is more durable and visually appealing than labels, providing a professional look. The inks used are ROHS compliant.